Due Diligence

We have designed this service focusing on industrial needs. Top Notch Service within your range

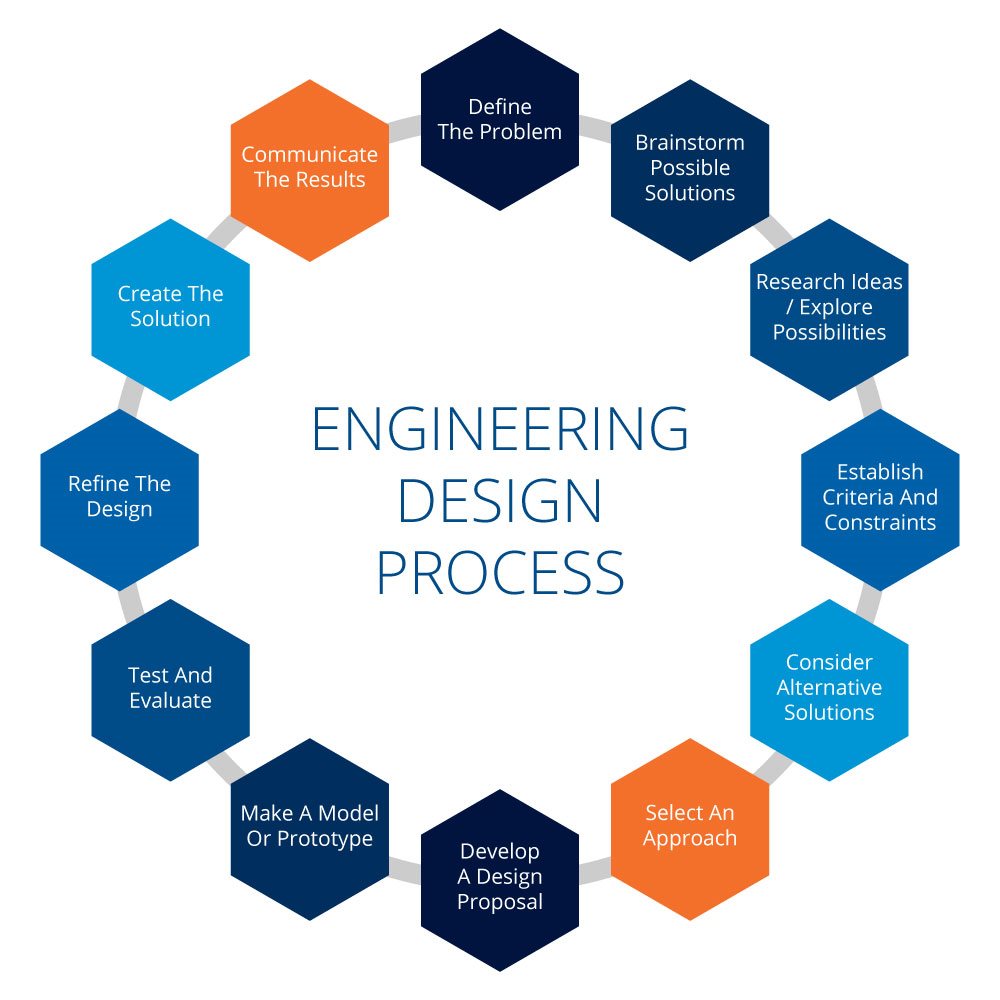

While the design process is iterative it follows a predetermined set of steps, some of these may need to be repeated before moving to the next one. This will vary depending on the project itself, but allows lessons to be learnt from failures and improvements to be made.

The process allows for applied science, mathematics and engineering sciences to be used to achieve a high level of optimisation to meet the requirements of an objective. The steps include problem solving processes such as, for example, determining your objectives and constraints, prototyping, testing and evaluation.

The steps of the engineering process are not always followed in sequence, but it is common for engineers to define the problem and brainstorm ideas before creating a prototype test that is then modified and improved until the solution meets the needs of the engineers project. This is called iteration and is a common method of working

We undertake due diligence of operating/idle plants for take-over for our clients so as to enable them to evaluate the assets in terms of value, suitability for their targeted products, quality and cost of production for intended products, possibility of future expansions/diversification. We work with the client to ensure that they make a good calculated business decision.